TOC 清洁验证的应用和优势

2023-03-29

总有机碳 (总有机碳) 清洁验证是制药和其他行业确保生产设施和设备清洁无污染的重要过程. 以下是 TOC 清洁验证的应用和优势:

Applications of TOC cleaning verification

TOC analysis is a popular method for cleaning validation as it enables simple, rapid measurements and can detect all organic substances. TOC analyzers are mainly used for water quality analysis of liquid samples such as tap water, environmental water, and waste water. Installing special accessories makes it possible to measure nitrogen components in liquid samples and carbon components in solid samples. TOC analyzers have recently been introduced not only for pharmaceutical products but also for cleaning validation at cosmetics and food manufacturing sites. They are also used in the manufacturing process and quality evaluation of various medical devices to evaluate the cleanliness of products after cleaning.

The following three methods can be proposed for cleaning validation using a TOC analyzer. The method used depends on the material, 尺寸, and shape of the equipment or products subject to cleaning validation.

- Rinse Sampling – TOC Measuring Method

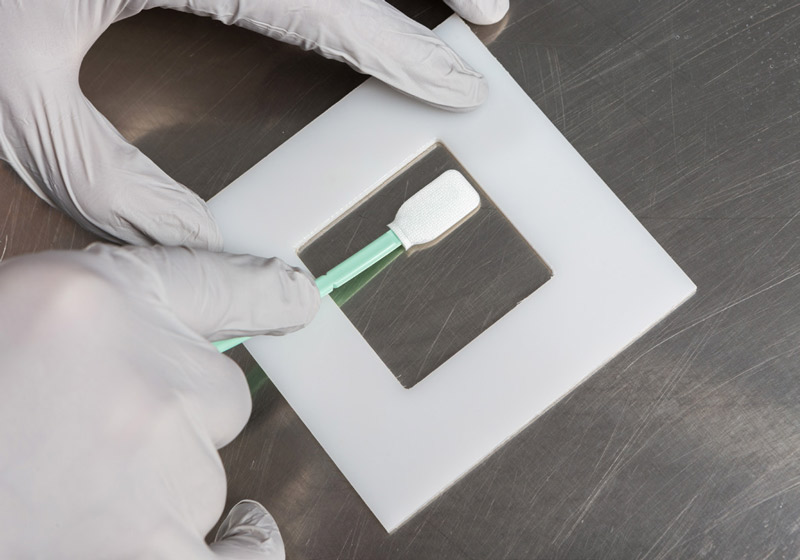

- Swab Sampling – 萃取 – TOC Measuring Method

- Swab Sampling – Direct Combustion Carbon Measuring Method

Benefits of TOC cleaning verification

The key Benefit of using TOC for cleaning validation is that it gives a quantitative value of the entire formulation, degradants, and cleaning agents combined for a more comprehensive understanding of cleanliness. Non-specific methods like TOC have more sensitive limits of detection (LOD) as compared to specific methods like HPLC. TOC provides greater sensitivity while also capturing. TOC and conductivity are the most common non-specific methods deployed for cleaning validation, verification, and monitoring.

Other benefits of using TOC for cleaning validation include:

- Universality: The TOC method is universal and can detect all organic substances, which saves time and labor costs for pharmaceutical companies.

- Simple and Rapid Measurements: TOC analyzers are mainly used for water quality analysis of liquid samples and can provide simple and rapid measurements.

- Expandability: Installing special accessories makes it possible to measure nitrogen components in liquid samples and carbon components in solid samples, which makes TOC analyzers versatile and expandable.

- 性价比高: TOC analysis is a cost-effective method for cleaning validation as it can detect all organic substances in a single run.

综上所述, TOC cleaning verification is an essential process in pharmaceutical manufacturing and other industries to ensure that manufacturing facilities and equipment are clean and free from contamination. The benefits of using TOC for cleaning validation include universality, simple and rapid measurements, expandability, cost-effectiveness, and more sensitive limits of detection.